An industrial air compressor is a machine that uses an electric or gas-powered motor to release the potential energy of pressurized air into power. A cylinder, or cylinders, are filled with extra air using a variety of air compressor techniques, thereby increasing the pressure. When the pressure exceeds its maximum level, the compressor turns off and rests in the tank until needed. Using kinetic energy as the tank depressurizes, the compressed air can be applied to several different tasks. The air compressor starts up once again to repressurize when the compressed air reaches its lowest point in the tank. Read More…

At OTC Industrial Technologies, we take pride in providing high-performance air compressor solutions that keep industries running efficiently. Our experience spans decades of designing, distributing, and servicing compressed air systems for a wide range of applications.

At Compressed Air Systems Incorporated, we take pride in delivering high-performance air compressors engineered for reliability, efficiency, and longevity. We specialize in designing and supplying a wide range of compressor solutions, including rotary screw, reciprocating, and oil-free models tailored to meet diverse industrial requirements.

Kaishan Compressor USA is a renowned leader in the field of air compressors, dedicated to delivering cutting-edge compressed air solutions to meet the diverse needs of industries across the United States. With a strong commitment to innovation, quality, and customer satisfaction, we have established ourselves as a trusted partner for businesses seeking reliable and efficient compressed air...

At Alkin Compressors, we are committed to delivering superior products that meet the exacting standards of the defense industry. With our comprehensive range of air compressors, fill stations, boosters, nitrogen production systems, and filter groups, we aim to provide reliable, efficient, and tailored solutions to our valued customers.

More Industrial Air Compressor

The amount of pressure that is released when an air compressor operates is as follows:

- Low-pressure air compressors produce pressures of 150 psi or less.

- Medium-pressure air compressors produce pressures of 151 to 1000 psi.

- High-pressure air compressors deliver pressures of more than 1,000 psi.

Positive displacement and dynamic displacement are the two categories under which the air compression process can be separated.

Positive Displacement

In positive displacement, air is forced into a chamber and, then, the chamber’s volume is reduced to compress the air. The compressed air is pushed out of the compression chamber and into the exit system when the maximum pressure is reached.

Dynamic Displacement

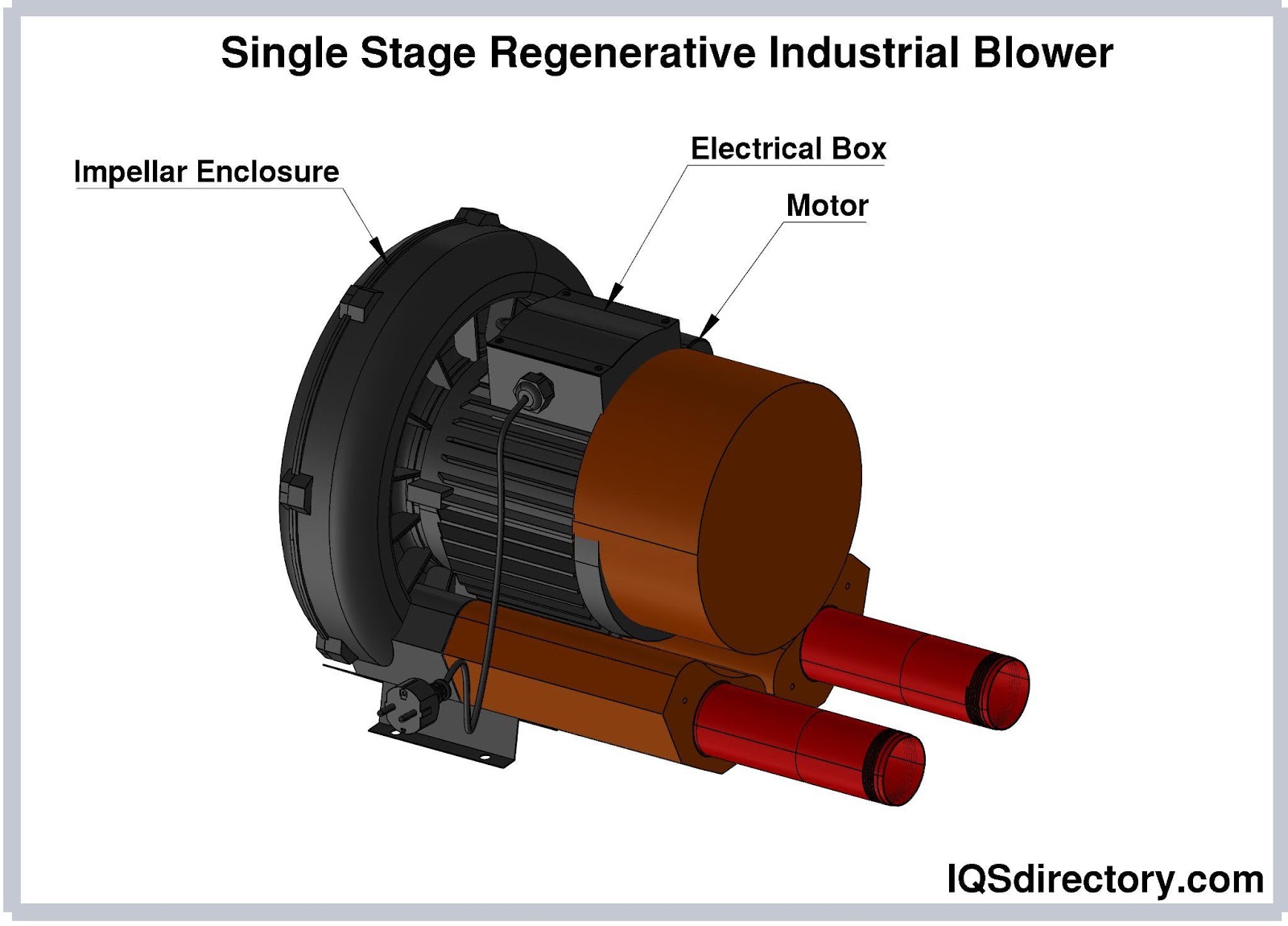

In dynamic displacement compressors, the air is given kinetic energy by a rotating component and then compressed. The air is accelerated and decelerated by the rotating component, which results in pressurization.

Types Of Industrial Compressors And How They Operate

Reciprocating Air Compressors

A piston is used by a reciprocating air compressor, a positive displacement kind of compressor, to compress and move air inside the compression chamber. These compressors are easy to move around and may be used remotely since they have one or more cylinders, a crankshaft, and a valve head, and they can be powered by an electric or gas engine.

They will require frequent lubrication because they have more working parts than other varieties of compressors. The pressurized air is then released through a valve into a storage tank, where it is kept until needed.

The amount of pressure delivered by reciprocating compressors can be either single- or two-stage.

Single-Stage Compressor

The air is only compressed once in a single-stage compressor. It entails the following actions:

- The compression cylinder draws air in.

- After that, a piston compresses the air in a single motion.

- The compression cylinder draws air in.

Two-Stage Compressor

The procedure for a two-stage compressor is the same as for a single-stage compressor except that, before the compressed air is drawn into a storage tank, it undergoes a second stroke. After being stored, the double-pressurized air is used to power powerful machinery.

Reciprocating compressors can be utilized in a variety of settings, such as chemical factories, oil refineries, and the processing of natural gas. They also have a big impact on agriculture, auto shops, and refrigeration technologies. Additionally, reciprocating compressors are more maintenance-intensive than other compressors in the same price range despite being more energy-efficient.

Rotary Vane Compressors

In contrast, rotary vane compressors use a slotted rotor with blades positioned all around the rotor to direct and compress air inside the chamber. As the blades enter and exit the rotor, compression pockets are created. The air volume gradually decreases as the rotor turns, increasing pressure. This technique is incredibly effective and has a long lifespan.

Rotary vane compressors offer improved energy efficiency for a variety of air demand applications, including automotive and agricultural. Additionally, they require less energy than their rotary-screw counterparts while still providing a continual energy supply.

Rolling Piston Compressors

Rolling piston compressors pressurize/force air against a stationary vane using a moving piston. By dividing the rotor and the vane with the piston, which reduces the chamber's volume, ambient gasses are compressed. Ideally, rolling air compressors offer a constant flow of compressed air while operating at higher speeds than conventional reciprocating pistons. These compressors are typically employed in cooling applications with a 15 kW maximum capacity.

Ionic Liquid Piston Compressor

Ionic liquid piston compressors pressurize the air using an ionic liquid piston rather than a typical metal piston. In general, this liquid piston lessens the requirement for bearings and seals, which contributes to the compressor's increased efficiency. In applications involving highly-volatile gasses, such as hydrogen filling stations and other hydrogen-based applications, these compressors are particularly helpful.

Scroll Compressors

To compress air or liquids, scroll compressors use two interlocking spiral-shaped vanes. One of the vanes is typically fixed, and the opposite eccentrically orbits so that air can be trapped and compressed in between before being released at the outlet port. Due to the decreased volume clearance between the fixed and orbiting vanes, as well as the lack of suction valves which cause pressure losses, these compressors also have high volumetric efficiency.

Centrifugal Compressors

Centrifugal compressors are rotational types of compressors that propel gasses into the cylinder where they are transformed into pressurized energy using a very fast spinning disk. They also have a diffuser, sometimes known as a diverging duct, which transforms velocity energy into pressured air. These compressors are used in commercial applications like natural gas, petrochemical, and industrial refrigeration.

Diagonal Compressors

Similar to centrifugal compressors in operation, diagonal compressors are also called mixed-flow compressors. However, the outlet from the rotor of a diagonal compressor has an axial and radial high-velocity disk.

Choosing the Proper Industrial Air Compressor Manufacturer

To make sure you have the most positive outcome when purchasing an Industrial Air Compressor from an Industrial Air Compressor Company, it is important to compare at least 5 Companies using our list of Industrial Air Compressor companies. Each Industrial Air Compressor Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Industrial Air Compressor business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Industrial Air Compressor companies with the same message.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services