A mini air compressor is a device that condenses air into a smaller volume so that it can be pressurized and used to generate pneumatic power. Mini air compressors are generally powered by rechargeable batteries or electricity because gas tanks add weight and bulk to the machine. Read More…

At OTC Industrial Technologies, we take pride in providing high-performance air compressor solutions that keep industries running efficiently. Our experience spans decades of designing, distributing, and servicing compressed air systems for a wide range of applications.

At Compressed Air Systems Incorporated, we take pride in delivering high-performance air compressors engineered for reliability, efficiency, and longevity. We specialize in designing and supplying a wide range of compressor solutions, including rotary screw, reciprocating, and oil-free models tailored to meet diverse industrial requirements.

Kaishan Compressor USA is a renowned leader in the field of air compressors, dedicated to delivering cutting-edge compressed air solutions to meet the diverse needs of industries across the United States. With a strong commitment to innovation, quality, and customer satisfaction, we have established ourselves as a trusted partner for businesses seeking reliable and efficient compressed air...

At Alkin Compressors, we are committed to delivering superior products that meet the exacting standards of the defense industry. With our comprehensive range of air compressors, fill stations, boosters, nitrogen production systems, and filter groups, we aim to provide reliable, efficient, and tailored solutions to our valued customers.

More Mini Air Compressor

Mini Air Compressors: Ultimate Guide to Compact, Portable Air Compression Solutions

Mini air compressors, also known as portable air compressors or compact air compressors, have become essential tools for DIY enthusiasts, automotive professionals, contractors, and hobbyists. Their small size, lightweight build, and versatility make them an ideal solution for a wide variety of pneumatic applications, from inflating tires to powering air tools. This comprehensive guide explores the working principles, types, benefits, use cases, decision factors, and supplier selection tips to help you find the best mini air compressor for your needs.

How Mini Air Compressors Work

When atmospheric air is compressed, potential energy is created that can be stored in a tank for later use. When the compressed air is purposefully released, pressure builds up similar to an open balloon, transforming the potential energy into useful kinetic energy. From there, different pneumatic tools can be powered by utilizing this energy transfer. 12-volt compressors use a motor to push air into an object straight from the atmosphere. Because of this, they are less useful for use with inflatable objects where a huge volume of air must be pumped to the desired pressure level.

Positive displacement: This technique draws air into a chamber and is used by the majority of air compressors. In order to compress the air, the machine reduces the chamber's capacity. It is then transferred into a storage tank and kept for a later use.

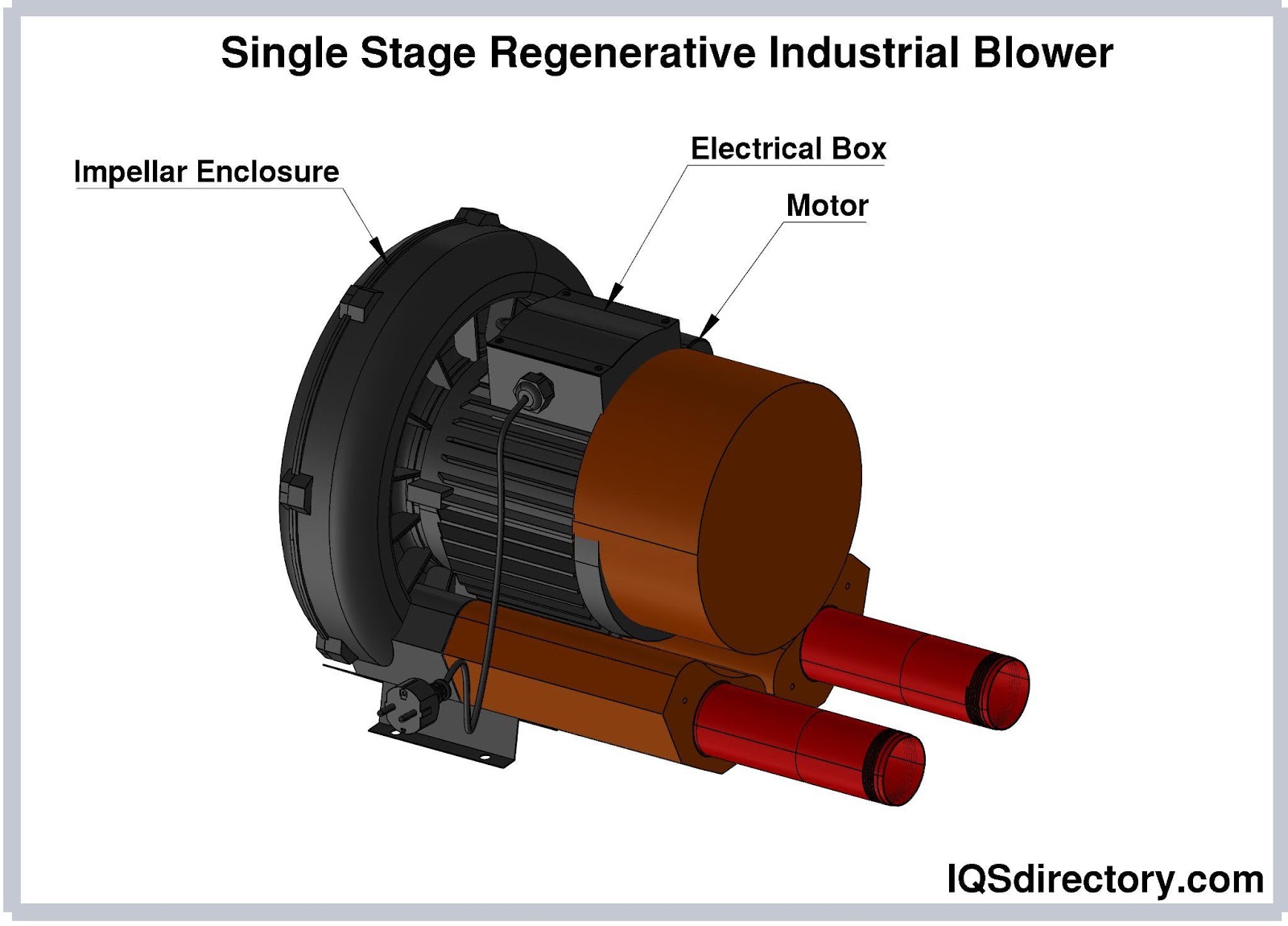

Dynamic displacement: Also known as nonpositive displacement, this technique introduces air into the chamber using an impeller with moving blades. Air pressure is created more quickly thanks to the energy generated by the blades' action. Turbocompressors use dynamic displacement because it produces enormous quantities of air quickly and efficiently. Air compressor utilizing dynamic displacement are frequently used in automotive turbochargers.

Key Components of Mini Air Compressors

- Compressor Pump: The central part that compresses air, usually using piston, rotary screw, or diaphragm mechanisms in mini models.

- Pressure Switch: Automatically turns the compressor on or off to maintain safe, consistent pressure levels.

- Regulator and Gauges: Allow users to adjust and monitor air pressure delivered to tools and accessories.

- Air Storage Tank: Stores compressed air for immediate use (some ultra-portable models are tankless).

- Safety Valve: Prevents over-pressurization, a critical feature for safe operation.

- Power Source: Electric, battery, or 12-volt DC power options, depending on model.

Common Mini Air Compressor Applications

- Inflating Tires: Cars, bicycles, motorcycles, and sports equipment.

- Powering Pneumatic Tools: For light-duty nailing, stapling, airbrushing, and cleaning tasks.

- Emergency Roadside Assistance: Rapid tire inflation in vehicles or RVs.

- Hobby and Craft: Airbrushing models, painting, or dust removal.

- General Household Tasks: Blowing dust from electronics, inflating pool toys, or cleaning tight spaces.

How Does an Air Compressor Regulator Work?

The air tank outlet on the compressor has a regulator attached with a pressure gauge and an adjustable knob. When a knob is turned counterclockwise, pressure is applied to a spring, which in turn closes a valve and lowers the pressure by restricting airflow into the regulator. As the user cranks the knob counterclockwise, the spring and valve release, enabling additional high-pressure air to flow through the exit.

Many single-stage air compressors have a default pressure limit of 125 psi. When this limit is reached, a pressure switch shuts off the motor and stops the compressed air production. Many compressors have air lines linked to regulators because one does not typically need to operate at that pressure limit. Using a regulator, one may enter the correct pressure setting for a particular tool.

When the pressure needed to power the tool is less than the pressure in the air pressure tank, a regulator adjusts the pressure. The regulator makes sure that the tool gets a consistent flow of air at the right pressure even if it cannot increase the pressure above what is already in the tank.

The piston, which allows air (or another gas) into or cuts off the supplied air for the cylinders, may be halfway through a stroke with pressurized air in the chamber when the regulator stops the pump. This is because the regulator stops the pump at any point throughout its cycle when the target pressure is reached. This trapped air could put undue pressure on the starting circuit by requiring more power to re-start the motor. An unloader valve, a simple addition, is added to address this problem by releasing the trapped air.

A regulator is flanked by two gauges, one to monitor tank pressure and the other to monitor airline pressure. The tank also has an emergency valve that activates in the event that the pressure switch malfunctions.

Why Is a Regulator Important for Mini Air Compressors?

- Tool Compatibility: Different pneumatic tools and inflatables require different operating pressures. Regulators ensure safe and efficient operation.

- Energy Efficiency: Avoids over-pressurization, reducing energy consumption and wear on components.

- User Safety: Prevents accidental bursts or injuries from excessive pressure.

Types of Mini Air Compressors

Electric Mini Air Compressors

An electric supply and a power outlet are necessary for an electric air compressor to function correctly. Usually supplied by alternating current, this kind of tiny air compressor needs a plug with at least a normal 120-volt rating. The power rating of electric air compressors is typically higher than that of other kinds of mini air compressors. Electric air compressors have the significant drawback of being less portable than other varieties because they need a power outlet and cord to function. These models are ideal for workshops, garages, and home use where a steady power source is available. They are favored for their low maintenance requirements, quiet operation, and ability to handle moderate-duty tasks like inflating tires, airbrushing, or powering pneumatic brad nailers.

Key Features of Electric Mini Air Compressors

- Consistent power output for longer tasks

- Lower noise levels compared to gas-powered models

- Available in oil-free and oil-lubricated designs

- Best suited for indoor, stationary use

Battery-Powered Mini Air Compressors

The battery-powered mini air compressor is lighter and more transportable. Typically, a rechargeable battery powers this kind of air compressor. Although their power rating may not be as high as that of electric air compressors, battery-powered air compressors are a great alternative for users who want to move the air compressor about the job site, vacation with it, or have it handy for emergency road situations.

For added convenience, many battery-powered air compressors can also be powered by the cigarette lighter in a car; if not, one should always keep an extra battery on hand to avoid running out of power when working with them for a lengthy amount of time.

Advantages of Battery-Powered Models

- True portability for on-the-go air supply

- No need for external power outlets

- Perfect for car emergency kits, camping, or remote job sites

- Rechargeable and often support USB or 12V charging

12-Volt (DC) Mini Air Compressors

12V air compressors are specifically designed for automotive and travel use. They plug directly into a vehicle’s cigarette lighter or 12V accessory port, making them an essential tool for inflating car and bike tires, sports equipment, and even small air mattresses while on the road. These compact air compressors are engineered for rapid inflation but are generally not suitable for heavy-duty pneumatic tools.

Oil-Free vs. Oil-Lubricated Mini Air Compressors

- Oil-Free: Require less maintenance, are lighter, and suitable for clean applications like painting or inflating food-grade equipment.

- Oil-Lubricated: Offer better durability and cooling for frequent or extended operation, but require regular oil checks and changes.

Looking for the best mini air compressor for your application?

Ask yourself: Do I need maximum portability, higher power output, or specialty features like automatic shutoff or integrated gauges? Explore 12V air compressors for automotive use, or compare electric and battery-powered models for home, workshop, or travel scenarios.

Benefits of a Mini Air Compressor

- Portability: The portability of mini air compressors is perhaps the biggest benefit. This equipment is small and lightweight enough for one to conveniently move it around their home or workplace, or easily stow it inside the back of a truck or car.

- Cost-Efficiency: Compared to their larger-sized equivalents, mini air compressors are very affordable. Whereas many industrial air compressors provide air more rapidly and with a higher psi ranking, they also come at much steeper prices. For typical usage around homes or for minor commercial applications, portable air compressors are suitable for such needs and are much more affordable.

- User-Friendly: The majority of the time, mini air compressors are simple to use and run. Because of their small size, one does not have to worry about a mini air compressor being too powerful or too heavy to operate with only one person.

- Versatility: Mini air compressors can be used for a diverse range of applications, including inflating tires, airbrushing, cleaning electronics, powering small pneumatic tools, and more.

- Energy Efficiency: Smaller compressors use less electricity or battery power, making them economical for intermittent, light-duty tasks.

- Low Maintenance: Oil-free models require minimal upkeep—ideal for users who want a hassle-free experience.

- Emergency Readiness: Compact compressors are invaluable in roadside emergency kits for quick tire inflation or minor repairs.

Who Should Use a Mini Air Compressor?

- Automotive enthusiasts needing a portable solution for tire inflation and maintenance

- Homeowners seeking easy-to-use tools for inflating sports equipment, pools, or air mattresses

- DIYers and hobbyists involved in airbrushing, crafting, or small repairs

- Contractors or professionals requiring light-duty pneumatic power for remote or hard-to-reach worksites

Wondering how a mini air compressor compares to standard and industrial models?

Mini air compressors are designed for portability and convenience, making them ideal for personal, light-commercial, and travel use. In contrast, standard and industrial air compressors provide higher CFM (cubic feet per minute) and PSI (pounds per square inch) ratings, supporting heavy-duty tools and continuous operation. If you need a compressor for demanding industrial applications, consider exploring industrial air compressor solutions.

Factors to Consider When Buying a Mini Air Compressor

- CFM and PSI Ratings: Ensure the compressor can deliver adequate airflow (CFM) and pressure (PSI) for your intended tools or tasks.

- Power Source: Choose between electric, battery, or 12V DC models based on your portability and usage requirements.

- Tank Capacity: Larger tanks allow for longer, uninterrupted operation; tankless models are ultra-portable but may require rest periods.

- Noise Level: Important for indoor or residential use; look for decibel ratings if quiet operation is a priority.

- Portability Features: Built-in handles, lightweight construction, and compact size are key for mobile use.

- Duty Cycle: Indicates how long the compressor can run before needing a cooldown—important for repetitive or prolonged jobs.

- Included Accessories: Check for inflation nozzles, hoses, adapters, and carrying cases.

- Warranty and Support: Reputable brands offer strong warranties and customer service.

Frequently Asked Questions About Mini Air Compressors

- What is the best mini air compressor for car tires?

Look for a 12-volt portable air compressor with a minimum PSI of 100-150, a built-in pressure gauge, and a long power cord for easy reach. Battery-powered models are also popular for roadside emergencies. - Can I use a mini air compressor for airbrushing?

Yes, but ensure the compressor offers stable airflow (CFM) and an adjustable regulator for precise control. Oil-free, quiet-running models are preferred for airbrushing. - How do I maintain a mini air compressor?

Oil-free models require little maintenance. For oil-lubricated types, regularly check and refill the oil. Always drain the tank after use to prevent moisture buildup and corrosion. - Is a mini air compressor powerful enough for pneumatic tools?

Mini air compressors can power low-demand tools like brad nailers, staplers, or airbrushes. For high-consumption tools (impact wrenches, grinders), a larger compressor is needed.

Choosing the Right Mini Air Compressor Supplier

To make sure you have the most constructive outcome when purchasing Mini Air Compressors from a Mini Air Compressor Manufacturer, it is important to compare at least 4/5 Companies using our Mini Air Compressor directory. Each Mini Air Compressor Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Mini Air Compressor company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Mini Air Compressor businesses with the same quote.

What to Ask Mini Air Compressor Suppliers?

- What warranty and after-sales support are included?

- What is the recommended maintenance schedule for your models?

- Can you provide references or reviews from previous customers?

- Are accessories, replacement parts, and repair services readily available?

- Do you offer bulk discounts for commercial or fleet buyers?

Ready to compare quotes or connect with top mini air compressor manufacturers?

Visit our mini air compressor suppliers directory to review detailed company profiles, preview manufacturer websites, and submit your project requirements for competitive pricing and expert guidance.

Summary: Why Choose a Mini Air Compressor?

Mini air compressors deliver unmatched convenience, portability, and versatility for users requiring a compact air supply solution. Whether you are inflating tires, powering light pneumatic tools, or seeking a reliable emergency air source, these small compressors combine ease of use with practical power. By understanding the different types, key features, and purchase factors—and by working with reputable suppliers—you can invest in the right mini air compressor for your needs, boosting productivity and peace of mind wherever you go.

Explore More About Air Compressors

- Interested in heavy-duty applications? Learn about industrial air compressors.

- Need 12V solutions for automotive use? Read our 12V air compressor guide.

- Want to know more about compressor maintenance? Browse our air compressor maintenance resources.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services