Environments such as medical offices, food processing plants, tattoo shops, clean room environments, research laboratories, public buildings and critical manufacturing lines require air that is 100% clean of microscopic oil particles that can contaminate both the equipment and the product. If the air output of oilless air compressors contains any oil in the air, no matter how small the amount, it is unacceptable for these environments. Read More…

At OTC Industrial Technologies, we take pride in providing high-performance air compressor solutions that keep industries running efficiently. Our experience spans decades of designing, distributing, and servicing compressed air systems for a wide range of applications.

At Compressed Air Systems Incorporated, we take pride in delivering high-performance air compressors engineered for reliability, efficiency, and longevity. We specialize in designing and supplying a wide range of compressor solutions, including rotary screw, reciprocating, and oil-free models tailored to meet diverse industrial requirements.

Kaishan Compressor USA is a renowned leader in the field of air compressors, dedicated to delivering cutting-edge compressed air solutions to meet the diverse needs of industries across the United States. With a strong commitment to innovation, quality, and customer satisfaction, we have established ourselves as a trusted partner for businesses seeking reliable and efficient compressed air...

At Alkin Compressors, we are committed to delivering superior products that meet the exacting standards of the defense industry. With our comprehensive range of air compressors, fill stations, boosters, nitrogen production systems, and filter groups, we aim to provide reliable, efficient, and tailored solutions to our valued customers.

More Oilless Air Compressor

Oilless Air Compressors: The Complete Guide to Oil-Free Compressed Air Solutions

Oilless air compressors—also known as oil-free air compressors—are engineered for industries and applications that demand high-quality, contaminant-free compressed air. These advanced machines have become the preferred choice for critical environments such as metal processing, electronics manufacturing, semiconductor fabrication, food processing, chemical production, industrial operations, medical facilities, automotive plants, and aerospace engineering. Their growing popularity is driven by the need for reliable, energy-efficient, and clean air solutions across multiple sectors.

What Is an Oilless Air Compressor?

An oilless air compressor is a type of air compressor that eliminates the need for lubricating oil in the compression chamber. Unlike traditional lubricated compressors, oil-free models do not use oil to seal or cool the internal moving parts during operation. This design ensures that the compressed air remains completely free of oil contaminants, making it indispensable for sensitive processes and applications where air purity is critical.

Types of Air Compressors: Exploring Oil-Free Designs

There’s a wide variety of air compressors available on the market, each tailored to specific use cases and application environments. Key types include:

- Centrifugal air compressors

- Rotary screw air compressors (including oil-free variants)

- Reciprocating (piston) air compressors

- Mini air compressors (portable and compact models for light-duty tasks)

Each of these compressor types can be engineered with oil-free designs, and manufacturers increasingly offer oil-free rotary screw compressors and mini oil-free compressors to meet evolving industry requirements.

Why Choose an Oil-Free Air Compressor?

When evaluating air compressor options, buyers often ask:

- Which air compressor is best for medical or food-grade applications?

- How do oilless air compressors compare to lubricated models in terms of energy efficiency, maintenance, and total cost of ownership?

- What are the main advantages of oil-free compressors?

Let’s break down the key benefits and decision factors:

- Pure, Contaminant-Free Air: Ideal for industries where even trace amounts of oil can compromise product integrity, such as pharmaceuticals, electronics, and food and beverage processing.

- Low Maintenance Requirements: Without oil to change or manage, routine maintenance is simplified, reducing downtime and labor costs.

- Energy Efficiency: Modern oil-free compressors feature advanced engineering that delivers superior energy performance, often resulting in lower operating costs over the system’s lifespan.

- Eco-Friendly Operation: No risk of oil leaks or disposal issues, supporting stringent environmental compliance and green manufacturing initiatives.

- Compliance with Industry Standards: Essential for meeting stringent ISO 8573-1 Class 0 certification for air purity—required in many regulated industries.

Are Oil-Free Air Compressors More Expensive?

While it’s true that oilless air compressors may require a higher initial investment compared to conventional lubricated models, they become increasingly economical over time. The reduced maintenance needs, fewer replacement parts, and enhanced energy efficiency translate to lower total cost of ownership and potentially higher profit margins—especially in demanding, 24/7 production environments.

Understanding Oil-Free Air Compressor Technologies

Oil-free air compressors are available in several technology platforms, each with unique strengths and applications. The two most common types are:

- Centrifugal compressors

- Rotary screw air compressors

Centrifugal Compressors: High-Volume, Oil-Free Performance

Centrifugal air compressors, also known as turbo compressors, utilize a high-speed rotary impeller to accelerate incoming air or gas. As the air is drawn in through the compressor’s inlet, the impeller imparts high velocity, which is then converted to pressure as the air passes through a diffuser and exits via a discharge nozzle. Centrifugal compressors are inherently oil-free because they do not require lubricants in the air path. This makes them especially suitable for large-scale, high-flow industrial applications, such as:

- Petrochemical processing

- Power generation

- Municipal water treatment plants

- Compressed air systems for critical manufacturing

These compressors are valued for their high reliability, continuous-duty capability, and ability to deliver oil-free compressed air at high volumes and pressures.

Rotary Screw Oil-Free Air Compressors: Precision and Versatility

Oil-free rotary screw compressors feature two helical screws, or rotors, that mesh and rotate in opposite directions within a specially designed compression chamber. This action draws air in through an inlet port, compresses it between the rotors, and discharges it through an outlet port—all without introducing oil into the air stream. Recent advances in materials and engineering have made these compressors increasingly popular for precision applications, including:

- Medical device manufacturing

- Electronics assembly

- Food and beverage packaging

- Pharmaceutical production

- Paint spraying and finishing

Oil-free rotary screw compressors deliver exceptional reliability, consistent air quality, and flexible performance across a wide range of pressures and capacities.

Other Oil-Free Compressor Technologies

In addition to centrifugal and rotary screw compressors, buyers may encounter:

- Oil-free reciprocating (piston) compressors: Used for lower-volume, intermittent applications such as dental offices, laboratories, and small-scale food processing.

- Scroll air compressors: Known for their quiet operation and compact footprint, frequently used in medical and electronics applications demanding ultra-clean air.

- Mini oil-free compressors: Portable, lightweight solutions for laboratories, workshops, or point-of-use operations where space and mobility are critical.

Key Applications for Oilless Air Compressors

Are you researching the best air compressor for your industry? Oilless air compressors are essential for:

- Food and Beverage Processing: Ensuring that compressed air does not contaminate products or packaging lines.

- Medical and Dental Facilities: Delivering clean, dry, oil-free air for patient care, equipment operation, and laboratory applications.

- Pharmaceutical Manufacturing: Supporting sterile, regulated production environments where air quality is paramount.

- Electronics and Semiconductor Fabrication: Preventing even microscopic oil particles from interfering with sensitive components.

- Chemical and Petrochemical Plants: Providing safe, contaminant-free compressed air for process control and instrumentation.

- Automotive and Aerospace Manufacturing: Powering tools, robots, and assembly lines while protecting delicate parts from oil vapor.

- Textile and Paper Production: Avoiding oil spots and defects in finished goods.

Looking for guidance on which oil-free compressor is right for your business? Explore leading air compressor manufacturers and compare oil-free solutions based on your specific requirements.

How to Choose the Right Oil-Free Air Compressor

Choosing the best oilless air compressor involves evaluating several critical decision factors:

- Required air quality: Does your process require ISO 8573-1 Class 0 air purity?

- Capacity and pressure needs: What is your required flow rate (CFM) and pressure (PSI or bar)?

- Duty cycle: Will the compressor run continuously or intermittently?

- Noise level: Is quiet operation necessary for your facility or workspace?

- Space constraints: Do you need a compact or portable solution?

- Maintenance resources: What is your team’s capability for routine servicing?

- Total cost of ownership: Consider not just the purchase price, but energy usage, maintenance, and projected lifespan.

Curious about how oil-free air compressors compare to traditional lubricated models? Learn more about oil-free compressor advantages and how they meet the strictest industry standards.

Oilless Air Compressor Maintenance and Reliability

One of the most compelling advantages of oil-free compressors is reduced maintenance. With no oil to check, change, or dispose of, servicing is faster and easier. Modern designs use advanced sealing and cooling technologies—such as PTFE (Teflon) coatings, ceramic bearings, and water or air cooling systems—to enhance durability and extend service intervals. Typical maintenance for oil-free compressors includes:

- Filter replacement (intake and inline filters)

- Checking and cleaning intercoolers, aftercoolers, and condensate drains

- Inspecting belts, hoses, and electrical connections

- Monitoring control panels and system diagnostics

Looking to maximize uptime and compressor lifespan? Partnering with an experienced oil-free air compressor manufacturer or authorized service provider ensures access to genuine replacement parts, expert support, and tailored maintenance programs.

Oil-Free Compressor Energy Efficiency and Sustainability

Energy consumption is a major cost driver for any compressed air system. Modern oil-free compressors are designed for optimal efficiency, often featuring:

- Variable speed drives (VSDs) to match output with demand

- Integrated heat recovery systems for process or facility heating

- Advanced controls and smart monitoring for predictive maintenance

- Low-loss, direct-drive motor designs

By operating without oil, these compressors contribute to a cleaner environment and help organizations achieve sustainability goals—eliminating the risk of oil spills, reducing hazardous waste, and minimizing carbon footprint. Many facilities can also benefit from lower insurance costs and easier regulatory compliance when using oil-free compressed air systems.

Frequently Asked Questions about Oilless Air Compressors

- What industries require oil-free air compressors? Industries such as pharmaceuticals, food and beverage, electronics, healthcare, and chemical processing typically mandate the use of oil-free compressed air to ensure the highest levels of product safety and compliance.

- Can oil-free compressors handle high-pressure or high-volume applications? Yes. Modern oil-free centrifugal and rotary screw compressors are engineered to deliver robust performance at high pressures and large flow rates, meeting the needs of even the most demanding industrial applications.

- Are oil-free compressors noisy? Advances in enclosure design, vibration isolation, and sound-dampening technology have significantly reduced operating noise levels. Many oil-free compressors operate at dB levels suitable for installation in noise-sensitive environments.

- How long do oil-free compressors last? With proper maintenance and operating conditions, oil-free air compressors can deliver years of reliable, trouble-free service—often matching or exceeding the lifespan of lubricated models.

- Is there a trade-off in air quality or performance? Quite the opposite: oil-free compressors are specifically engineered to deliver the highest air purity, making them ideal for industries where quality and compliance cannot be compromised.

Future Trends in Oil-Free Air Compressor Technology

As industries continue to push for greater efficiency, sustainability, and automation, the oil-free air compressor market is evolving rapidly. Expect to see:

- Smart, IoT-enabled compressors for remote monitoring and diagnostics

- Improved energy recovery and heat management systems

- New materials for even longer-lasting wear surfaces and seals

- Compact, modular designs for easy expansion and integration

- Greater adoption of oil-free solutions in emerging clean-tech and life sciences sectors

Looking for the latest advancements in oil-free air compressor technology? Connect with leading manufacturers and explore innovative solutions tailored to your industry.

Conclusion: Is an Oilless Air Compressor Right for You?

Oilless air compressors represent the gold standard for clean, efficient, and reliable compressed air. Whether you’re operating in food production, medical technology, electronics, or any application where air purity and performance are non-negotiable, oil-free compressors deliver tangible value. Their combination of low maintenance, long lifespan, reduced environmental impact, and ability to meet the strictest air quality standards make them the preferred choice for forward-thinking businesses.

Ready to take the next step? Discover top oil-free air compressor manufacturers, compare product specifications, and request quotes tailored to your application. If you have more questions, explore our comprehensive oil-free compressor resources for detailed guides, technical data, and application tips.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

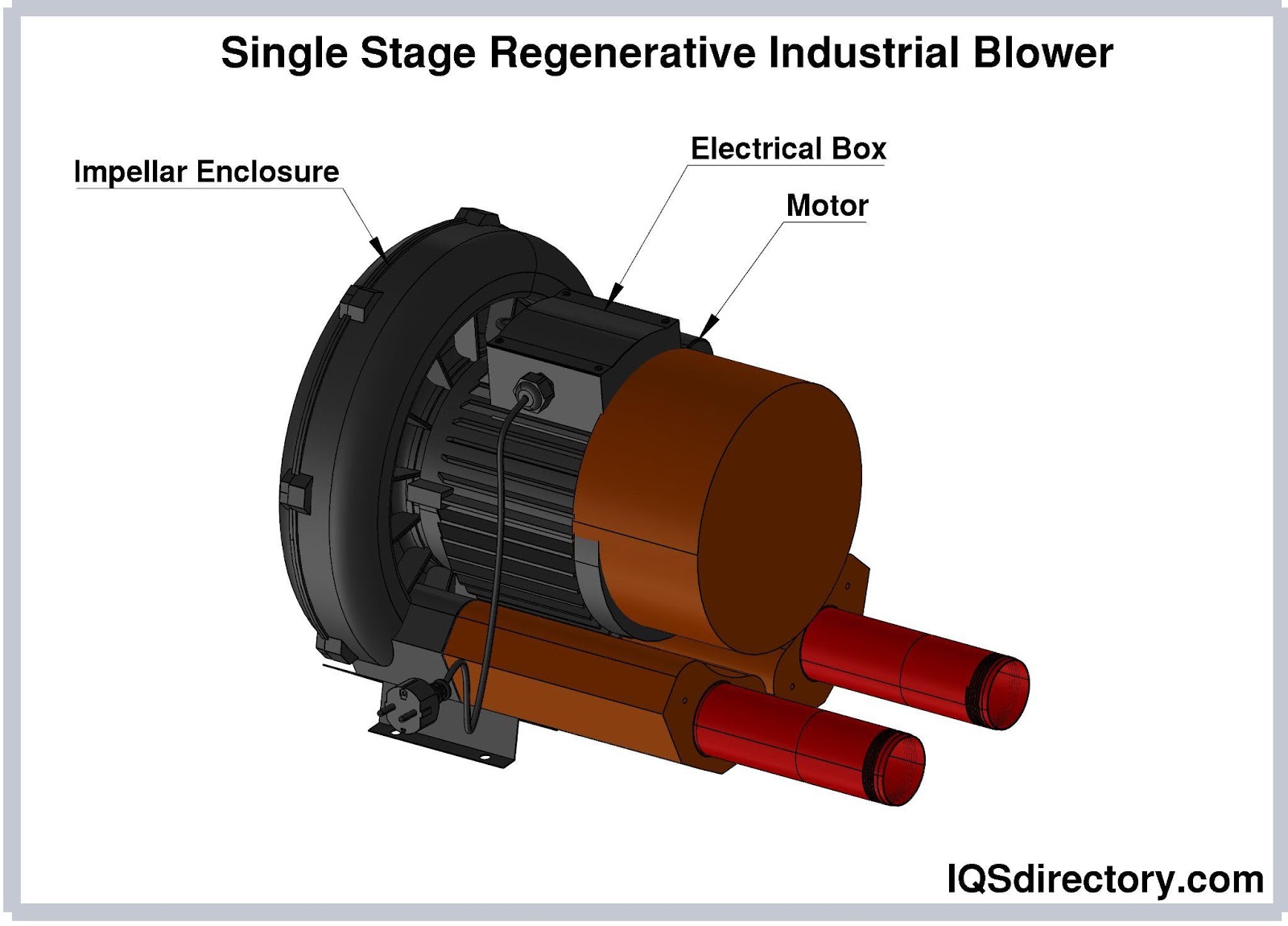

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services