A rotary compressor is a type of air compressor that creates compressed air using two rotating screws, commonly referred to as rotors. In comparison to other compressor types, rotary screw air compressors are cleaner, quieter, and more effective. They are also unbelievably dependable, even under continual use. Due to these reasons, rotary compressors are the go-to device for various business and industrial applications all over the world. Read More…

At OTC Industrial Technologies, we take pride in providing high-performance air compressor solutions that keep industries running efficiently. Our experience spans decades of designing, distributing, and servicing compressed air systems for a wide range of applications.

At Compressed Air Systems Incorporated, we take pride in delivering high-performance air compressors engineered for reliability, efficiency, and longevity. We specialize in designing and supplying a wide range of compressor solutions, including rotary screw, reciprocating, and oil-free models tailored to meet diverse industrial requirements.

Kaishan Compressor USA is a renowned leader in the field of air compressors, dedicated to delivering cutting-edge compressed air solutions to meet the diverse needs of industries across the United States. With a strong commitment to innovation, quality, and customer satisfaction, we have established ourselves as a trusted partner for businesses seeking reliable and efficient compressed air...

At Alkin Compressors, we are committed to delivering superior products that meet the exacting standards of the defense industry. With our comprehensive range of air compressors, fill stations, boosters, nitrogen production systems, and filter groups, we aim to provide reliable, efficient, and tailored solutions to our valued customers.

More Rotary Compressor

Operation of a Rotary Screw Feeder: How Do Rotary Screw Air Compressors Work?

Rotary screw compressors are foundational to modern industrial compressed air systems, renowned for their reliability, efficiency, and ability to provide a consistent supply of compressed air for a wide range of applications. But what exactly makes rotary screw air compressors so effective, and how do their components operate to produce compressed air under pressure? Understanding the inner workings of these machines is key for facilities managers, engineers, maintenance professionals, and anyone in the market for industrial air compressors.

The core operating principle of rotary screw air compressors lies in positive displacement compression technology. This method is both straightforward and ingenious, offering high efficiency and continuous duty cycles that set rotary screw compressors apart from other types of air compressors, such as reciprocating (piston) compressors or centrifugal compressors.

At the heart of a rotary screw air compressor are two interlocking helical rotors—often referred to as the male and female rotors. These rotors trap air between their threads as they rotate, reducing the volume of trapped air and increasing its pressure. The type of rotary screw compressor—oil-injected or oil-free—determines how these rotors are lubricated and sealed. Timing gears in a dry-running rotary screw compressor ensure precise alignment and prevent direct contact between rotors, while oil-flooded rotary screw air compressors (see screw compressor manufacturers) use lubricating oil to fill the space between rotors. The oil acts as a hydraulic seal, improves cooling, and enables more efficient energy transfer from the drive motor to the compressed air output.

Step-by-Step Operation of Rotary Screw Compressors

- Intake Process: When the rotary screw compressor starts, an intake valve opens, allowing ambient air or process gas to enter the compression chamber. The two helical screw rotors housed within the chamber begin to rotate at high speed, typically driven by an electric motor.

- Air Trapping and Movement: The rotating action of the rotors traps air in the cavities formed between their threads. As the rotors continue turning, these trapped pockets of air are isolated from the intake and forced down the length of the compressor chamber.

- Compression: As the air moves away from the intake valve and progresses along the chamber, the space between the rotor threads decreases. This reduction in volume results in an increase in air pressure.

- Air Condensation: With the rising pressure, the air is condensed and its temperature increases. In oil-flooded compressors, the injected oil absorbs some of this heat, improving thermal management.

- Discharge: Once the air reaches the end of the compression chamber and achieves the desired discharge pressure, a discharge valve opens. The compressed air is then released into a receiver tank or directly into the facility’s air distribution network.

- Post-Processing: The compressed air may undergo additional treatment—such as drying, filtration, or contamination removal—before being used in downstream equipment or pneumatic tools.

Why Choose Rotary Screw Compressors?

Are you researching the best industrial air compressor solution for your facility? Rotary screw compressors consistently rank as a top choice for businesses seeking a long-term, cost-effective, and low-maintenance compressed air system. Let’s explore the core benefits, energy efficiency, and versatility that make rotary screw compressors the preferred technology across countless industries.

- Superior Energy Efficiency: Rotary screw compressors deliver high volumetric efficiency and continuous duty cycles. Their compression mechanism minimizes energy losses compared to reciprocating compressors. Since energy costs represent a significant portion of overall compressed air expenses, investing in an energy-efficient rotary screw compressor can lead to substantial operational savings.

- Reliable Continuous Operation: Designed for long periods of dependable use, rotary screw compressors are ideal for demanding industrial environments where compressed air must be available around the clock. Their robust design and fewer moving parts reduce the risk of breakdowns and minimize required maintenance.

- Low Noise and Vibration: Thanks to their smooth rotary action, these compressors are much quieter than piston compressors. This low-noise characteristic allows for installation closer to the point of use, reducing distribution losses and making them suitable for workshops, manufacturing plants, and even smaller commercial spaces where noise regulations apply.

- Adaptability and Flexibility: Rotary screw air compressors are available in a wide variety of sizes, configurations, and drive types—such as direct drive, gear drive, and belt drive. Whether you require an oil-flooded or oil-free system, there is a rotary screw compressor tailored to your specific application, pressure, and flow requirements.

- Minimal Maintenance Requirements: These compressors are engineered for reliability and simplicity. Routine maintenance tasks—such as oil changes, filter replacements, and inspections—are straightforward, minimizing downtime and reducing ongoing operational costs.

Wondering if a rotary screw compressor is right for your industry? Explore our in-depth guides to rotary screw air compressor manufacturers and discover which models best meet your compressed air needs.

Rotary Screw Compressor Drive Types and Their Benefits

The method used to transfer power from the drive motor to the screw rotors is a significant factor influencing compressor performance, energy efficiency, and long-term reliability. Selecting the right drive system—belt drive, gear drive, or direct drive—can impact total cost of ownership and suitability for your specific industrial application. Let's compare the common rotary screw compressor drive systems in detail:

- Belt-Drive Rotary Screw Compressors: These compressors employ a belt and pulley assembly to transfer power from the electric motor to the screw rotors. Belt-driven rotary screw compressors are straightforward in design, relatively easy to install, and simple to maintain. Their lower upfront cost makes them an attractive choice for small businesses, workshops, and facilities with moderate compressed air demands.

Looking for an affordable industrial compressor solution? Belt-drive rotary screw compressors offer a balance between cost and performance, making them popular for light industrial and commercial use. - Gear-Drive Rotary Screw Compressors: Gear-driven systems eliminate belts and pulleys, using a series of gears to transmit power. This design reduces vibration, improves alignment, and increases energy efficiency. Gear-drive compressors tend to operate more quietly and are better suited for environments where low noise and consistent performance are critical. While they often come at a higher initial investment, their robust construction and energy savings can offset costs over time, especially for operations requiring large volumes of compressed air.

How do gear-drive compressors compare to direct-drive models? Gear-drive rotary screw compressors provide a middle ground between simplicity and advanced technology, making them ideal for manufacturers and processing plants demanding reliable, high-capacity air delivery. - Direct-Drive Rotary Screw Compressors: In direct-drive compressors, the motor shaft is directly coupled to the screw rotors. This eliminates any intermediary power transmission components, resulting in maximum mechanical efficiency and the lowest possible energy losses. Direct-drive compressors are the premium choice for high-end, critical applications where energy consumption, uptime, and minimal maintenance are top priorities. Their advanced design supports variable speed drive (VSD) options for further optimization.

Need the ultimate in performance and energy savings? Direct-drive rotary screw compressors deliver unmatched reliability, efficiency, and service life, making them the preferred choice for large-scale manufacturing, power plants, and highly regulated industries.

Choosing the right drive type depends on your facility’s specific air demand profile, energy efficiency goals, maintenance capabilities, and budget constraints. For a detailed assessment, consult with leading rotary screw compressor manufacturers for tailored recommendations.

Rotary Screw Compressor Applications: Where Are They Used?

Rotary screw air compressors are among the most versatile and widely adopted industrial air compressors in the market today. Their unique combination of high efficiency, continuous operation, and adaptability makes them suitable for a diverse array of applications, from heavy industry to precision manufacturing. Below are some of the most common use cases and industries where rotary screw compressors are indispensable:

- Manufacturing and Automation: Factories rely on rotary screw compressors to power pneumatic machinery, actuators, CNC equipment, robotics, and assembly lines. Their continuous duty cycle is ideal for environments that require a steady supply of high-pressure compressed air to ensure consistent production quality and throughput.

- Food and Beverage Processing: In food plants, rotary screw compressors are used for product handling, packaging, bottling, and cleaning operations. The availability of oil-free rotary screw compressors is critical when purity and contamination control are essential, such as in direct food contact or packaging.

- Pharmaceutical and Healthcare: The pharmaceutical industry demands ultra-clean, oil-free compressed air for production, packaging, and laboratory processes. Oil-free rotary screw compressors meet stringent regulatory and quality standards, ensuring product integrity and compliance.

- Construction and Mining: Portable rotary screw compressors provide mobile, on-demand compressed air for remote construction sites, mining operations, and infrastructure projects. Their rugged design and ease of transport make them invaluable for powering pneumatic tools, sandblasting, drilling, and other field applications.

- Automotive Industry: Automotive manufacturing plants and repair shops utilize rotary screw compressors for painting, tire inflation, assembly tools, and quality control testing.

- Electronics and Semiconductor Manufacturing: Sensitive electronics production processes require extremely clean and dry compressed air. Oil-free rotary screw compressors with integrated dryers and filtration systems ensure that only contaminant-free air reaches the production environment.

- Energy and Petrochemical: Oil-injected rotary screw compressors are used in gas processing, hydrocarbon refining, and petrochemical plants. Their robust construction supports high-volume, high-pressure applications and continuous duty cycles in demanding conditions.

- Other Industrial and Commercial Uses: Rotary screw compressors also support woodworking, textiles, plastics manufacturing, wastewater treatment, printing, HVAC controls, and more. Their adaptability makes them a mainstay for nearly any sector requiring reliable compressed air supply.

Searching for the best rotary screw compressor for your application? Consider your required air quality (oil-injected vs. oil-free), expected usage patterns, and industry-specific standards. Browse rotary screw compressor suppliers and request quotes for models built for your environment.

Oil-Free vs. Oil-Injected Rotary Screw Compressors: Which Is Right for You?

Selecting between oil-injected and oil-free rotary screw compressors is a critical decision for facility managers and engineers. Here’s a quick guide to help you determine which compressor type aligns with your operational requirements:

- Oil-Free Rotary Screw Compressors: These compressors use special materials, coatings, and timing gears to prevent rotor contact, eliminating the need for lubricating oil in the compression chamber. Oil-free compressors are essential for industries where air purity is paramount, such as food and beverage, pharmaceuticals, electronics, and medical device manufacturing. They meet stringent ISO 8573-1 Class 0 air quality standards and reduce the risk of contamination in sensitive processes.

Common Questions: “Do I need an oil-free air compressor for my application?” “What are the maintenance requirements for oil-free rotary screw compressors?” - Oil-Injected Rotary Screw Compressors: In these models, lubricating oil is injected into the compression chamber, sealing, cooling, and lubricating the rotors. Oil-injected compressors are ideal for general industrial use, powering pneumatic tools, HVAC controls, tire inflation, and other processes where air quality is less critical than reliability and performance. These compressors typically offer higher efficiency and lower initial cost compared to oil-free models.

Common Questions: “How do oil-injected rotary screw compressors compare to piston air compressors?” “What filtration options are available to remove oil aerosols from compressed air?”

To learn more about air quality standards, compressor sizing, and filtration options, explore oil-free rotary screw compressor manufacturers on our platform.

Factors to Consider When Choosing a Rotary Screw Compressor

Investing in a rotary screw air compressor is a major capital decision for any facility. To ensure you select the right system for your needs, consider the following key factors:

- Air Demand and Flow Rate: Calculate your facility’s required compressed air volume (measured in CFM or m³/h) and pressure (PSI or bar). Oversizing or undersizing your compressor can lead to energy waste or insufficient supply.

- Duty Cycle: Rotary screw compressors excel in continuous-duty applications. Assess how many hours per day and days per week the unit will operate to determine the optimal model.

- Air Quality Requirements: Identify whether your operation demands oil-free air, or if oil-injected compressors are sufficient. Consider adding dryers, filters, and separators for enhanced air quality.

- Installation Environment: Evaluate available space, ventilation, ambient temperature, and noise restrictions. Choose a compressor with appropriate enclosure, cooling, and sound attenuation features.

- Energy Efficiency: Look for models with variable speed drives (VSD), advanced controls, and high-efficiency motors to reduce energy consumption and operating costs.

- Maintenance and Support: Consider ease of maintenance, availability of consumables, and service support from your manufacturer or distributor.

- Total Cost of Ownership: Factor in initial investment, installation, energy use, maintenance, and potential downtime to evaluate long-term value.

Ready to compare options or request a quote? Use our rotary screw compressor supplier directory to find the best manufacturers for your requirements.

Choosing the Right Rotary Screw Compressor Manufacturer

Selecting the ideal rotary screw compressor manufacturer is essential to ensure you receive a system tailored to your industrial or commercial needs, backed by expert support and reliable service. The right partner will offer a range of products, application expertise, and responsive after-sales support. Here are some steps to guide your purchasing decision:

- Identify Your Application Requirements: Define your compressed air needs, including air quality, pressure, flow rate, and duty cycle.

What is your primary application? Are you looking for an oil-free compressor for food processing, or a high-capacity oil-injected model for manufacturing? - Research and Compare Leading Manufacturers: Use our comprehensive list of rotary screw compressor suppliers to compare at least 4 or 5 manufacturers. Review business profiles to assess experience, product range, certifications, and customer reviews.

- Request Custom Quotes: Each supplier profile features a direct contact form, enabling you to request detailed quotes and technical information tailored to your project.

- Evaluate Technical Support and Service: Consider the manufacturer’s commitment to training, maintenance support, spare parts availability, and warranty coverage.

- Use Our Website Previewer: Take advantage of our proprietary website previewer to explore each business’s specialties and offerings, ensuring a good fit for your requirements.

- Streamline the RFQ Process: Our request-for-quote (RFQ) form allows you to contact multiple rotary screw compressor businesses with the same inquiry, saving you time and encouraging competitive pricing.

Whether you’re upgrading an existing compressed air system, expanding production capacity, or designing a new facility, our manufacturer directory and expert resources are here to help you make an informed buying decision.

Frequently Asked Questions About Rotary Screw Compressors

- What maintenance is required for rotary screw compressors?

Routine maintenance includes changing oil and filters, inspecting belts or gears, checking for leaks, and monitoring control systems. Preventive maintenance schedules vary based on compressor type and usage level. - How long do rotary screw compressors last?

With proper maintenance, rotary screw compressors can last 10–15 years or longer. Oil-free models may require more frequent inspections of their special coatings and timing gears. - Can rotary screw compressors operate in high-temperature or harsh environments?

Yes, but selecting a compressor with suitable cooling, enclosure, and environmental protections is vital for reliable operation in demanding conditions. - What are the main differences between rotary screw and piston compressors?

Rotary screw compressors offer smoother, quieter, and more energy-efficient operation, with greater reliability and lower maintenance for continuous-duty applications. - How do I size a rotary screw compressor for my facility?

Assess your total air demand (CFM), required pressure (PSI), duty cycle, and future expansion plans. Consult with manufacturers for a customized sizing analysis.

Still have questions about selecting, installing, or maintaining rotary screw air compressors? Contact our experts or browse our knowledge base for comprehensive guides, troubleshooting tips, and application case studies.

Rotary screw air compressors represent a proven, efficient, and flexible solution for businesses seeking reliable compressed air. By understanding their operation, benefits, drive systems, and application versatility, you can make a well-informed decision to support your facility's productivity and growth.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

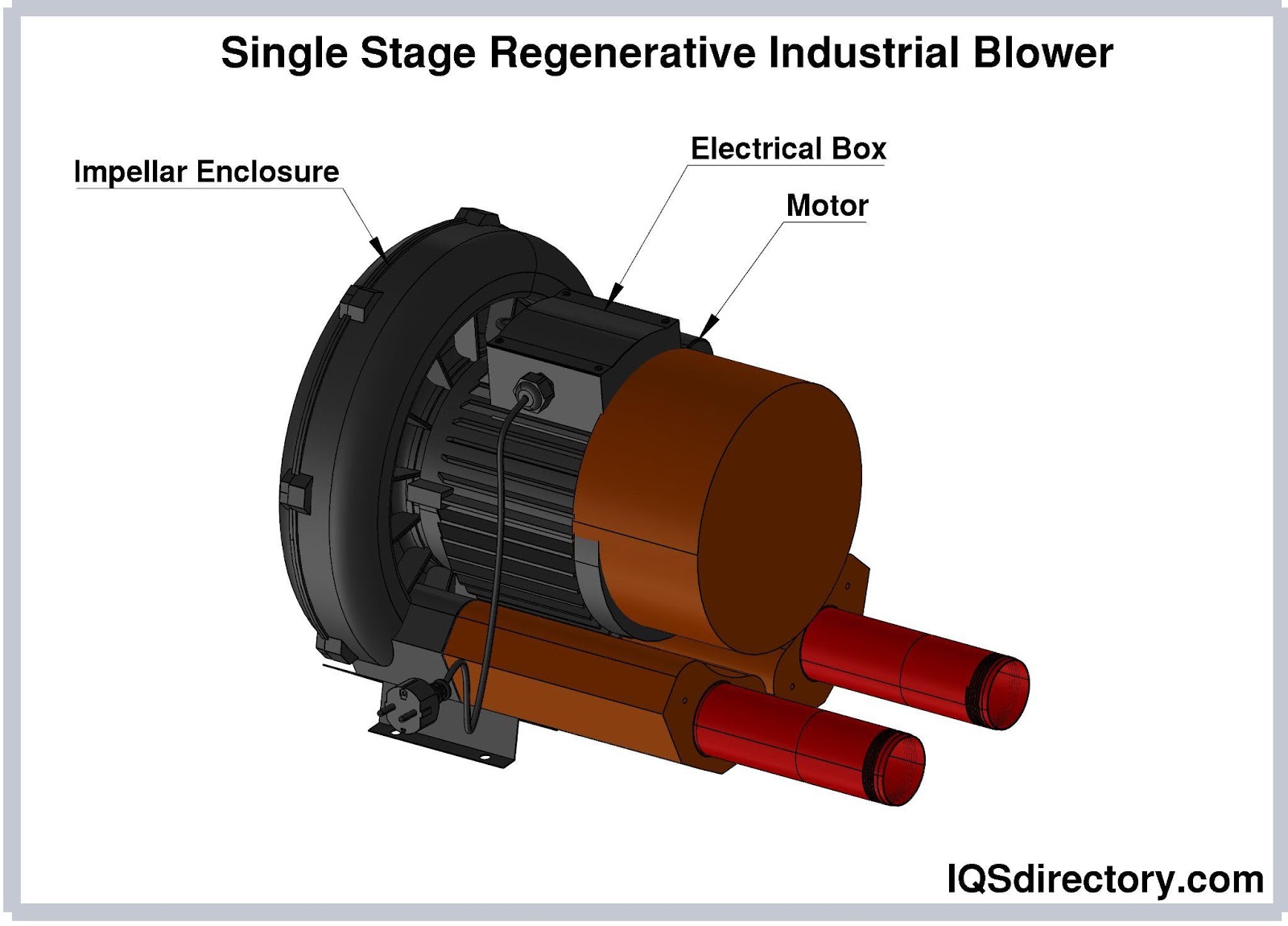

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services